Today's integrated power modules are addressing demanding size, weight, power budget and cost efficiency requirements to bring robotics from factory, residential and commercial applications into a vast new realm limited only by imagination.

OLogic ignites a new generation of mobile robots with advanced integrated power modules

Innovations in power conversion technology are revolutionizing robotic design. Today's integrated power modules are addressing the demanding size, weight, power budget and cost efficiencies needed to move robots from factory, residential and commercial applications into a vast new realm limited only by imagination.

We are at an inflection point where robots are bringing huge benefits to our lives. OLogic is a big reason we've seen them proliferate.

OLogic is a Santa Clara, California-based electronics consulting firm with over 15 years of experience helping its clients bring robotic designs to market in high or low volumes by providing electrical, mechanical, and industrial engineering support, as well as software and firmware engineering . This includes expertise in power electronics integration, a primary design consideration that determines the range, functionality and charging capabilities of mobile robots.

OLogic has designed dozens of robots for many industries, including agriculture, smart homes, and inventory control, to name a few. OLogic's robotics customer base can be traced back to a startup that is considered by many to be the granddaddy of mobile robotics in Silicon Valley. Willow Garage has drawn attention for its ability to combine off-the-shelf open-source software from universities and other entities to help robots perform difficult tasks.

When the company disbanded in 2014, it sparked an exodus of robotics software experts who have gone on to found nearly every major robotics startup in the Bay Area. This has opened up new businesses for Logic companies such as Savioke, Knightscope, Fetch and Dusty Robotics.

Ted Larson, CEO of OLogic, said: "The real rock stars in the robotics industry are those who do advanced software for things like machine learning or robot algorithmic task navigation. Electronics are an afterthought. What happens is that people think they You can buy all these off-the-shelf things and connect them. It quickly becomes a house of cards."

Bringing power to the foreground

Mobile robots have unique power challenges and require a range of power levels. Sensors, servo motors, actuators, data servers, communication systems, and other devices that operate robots have different power and power density requirements. Some devices have high power requirements. Other devices may not operate as often. This requires the ability to deliver power quickly, cleanly and economically from battery power.

"The parts we've been using the most lately are the Vicor ZVS buck regulators, and we're using them all over the place on mobile robots now," Larson said. "I never thought I'd need 5 or 10 amps for 12 volts, so I'm going to build My own power supply. I'll never think like that again."

Save time and money by automating building layout

Dusty Robotics (Dusty) is one customer that works closely with Logic to optimize its power conditions. Based in Mountain View, California, Dusty makes robot-powered tools for modern construction workers.

For centuries, the construction industry has used two simple tools to draw building plans: a tape measure and a chalk line. Even today, when architects use complex 3D CAD models to design buildings, the process still involves printing layouts on paper, dragging them to the job site, and transferring them to the ground by hand. The tape measure and mark process is slow and prone to human error, affecting schedule and budget. Errors lead to rework, which often accounts for 10 percent of a construction project's cost, according to Dusty.

Philipp Herget, co-founder and CTO of Dusty Robotics, said: "When plans are made by hand, there are a lot of mistakes, in fact a lot more than the construction industry knows. We've heard that layout mistakes make A case of a construction company going bankrupt. We prevent mistakes from happening because everything is marked correctly - not by hand, but by a robot."

Dusty FieldPrinter is 5x faster and has zero errors

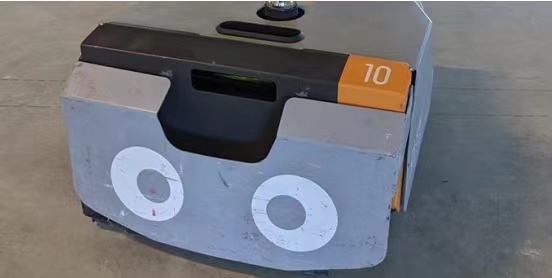

Dusty eliminates the traditional, labor-intensive process of physically transferring building plans to the ground, and robots programmed on the job site can automate the same tasks. The Dusty FieldPrinter robot loads a digital version of the floor plan, then prints the layout on the ground, such as walls, doors, water pipes and wireways. Also, it is five times faster than a human and does it within one-sixteenth of an inch.

This innovation helps the construction industry operate more like a digital manufacturer, improving consistency, predictability and reliability while improving the working conditions of skilled artisans at the heart of the construction process.

"If you can reduce the time allotted in your schedule, you can speed up the completion of construction, and the sooner the construction is completed, the sooner you can start collecting revenue," Herget said. "Time is money."

With long battery life and state-of-the-art power conversion technology, Dusty's robotics innovations are helping digitize the construction industry, creating a single source of truth based on digital models on the job site.

Powering the Dusty FieldPrinter Robot

Dusty's FieldPrinter is a battery-powered mobile robot designed for long-term operation in all weather conditions. It includes many different electronic devices, including sensors, drive motors and electrical components, a computationally intensive processor and a printer - all with different operating voltage and current requirements.

That's why Dusty hired Logic to build the core electronics for its robot. OLogic started with a discrete power solution. Over time, however, Vicor introduced Logic to a modular approach to building Power Delivery Networks (PDNs) for robots. OLogic realized that they couldn't design a product that was as operationally and thermally efficient as the Vicor power module, with a wide operating range. Additionally, Vicor modules, such as the ZVS buck regulator, are extremely cost-effective given the 200 to 300 watts of power and 97% efficiency they deliver.

With long battery life and state-of-the-art power conversion technology, Dusty's robotics innovations are helping digitize the construction industry, creating a single source of truth based on digital models on the job site. Instead of architects, general contractors and each trade partner working from their own paper plans, now everyone builds from a single design printed on the floor. The ability to provide a digital layout improves coordination among these myriad partners, enabling better planning, execution, and faster completion.

"Building automation is enhancing what humans can do," Herget said. "People used to use screwdrivers and now they use power tools. It's just making their jobs easier. Our robot-driven tools are bringing the construction industry to the next level. , creating better outcomes while also improving the working environment for skilled artisans."

About Vicor

Vicor Corporation is a leader in high-performance power modules, solving customers' toughest power challenges, enabling them to innovate and maximize system performance. Our easy-to-deploy power modules provide the highest density and efficiency, enabling advanced power delivery networks from source to point of load. Headquartered in Andover, Massachusetts, Vicor serves customers worldwide with unmatched power conversion and power delivery technologies.

About OLogic

OLogic is a team of designers and engineers who are passionate about development and new ideas. OLogic addresses customer needs with expertise in areas such as electronic design, embedded software, mechanical and industrial design, and low-cost design for manufacturing solutions.